Aerospace and aeronautical surface treatments for demanding aircraft components

Precision coating & plating for critical aerospace components, compliant with stringent aerospace standards.

Electropoli delivers highperformance coatings engineered for aircraft performance and lightweight durability, with full traceability and regulatory compliance.

Our AS9100-certified and NADCAP-approved processes ensure material integrity, lightweight performance, and durability for critical components in Aerospace and aircraft manufacturing.

Key Surface Treatments for Aerospace & Aeronautics Applications

Our expertise in Aeronautics surface treatment extends across all phases of component protection, including chemical conversion (e.g., SurTec 650, Alodine 2040), anodizing, Electroless nickel plating (ENP), plating (ZnNi as cadmium replacement), and painting.

Explore our advanced surface treatment processes engineered to meet the highest Aeronautics standards and guarantee lightweight durability and material protection for aircraft components.

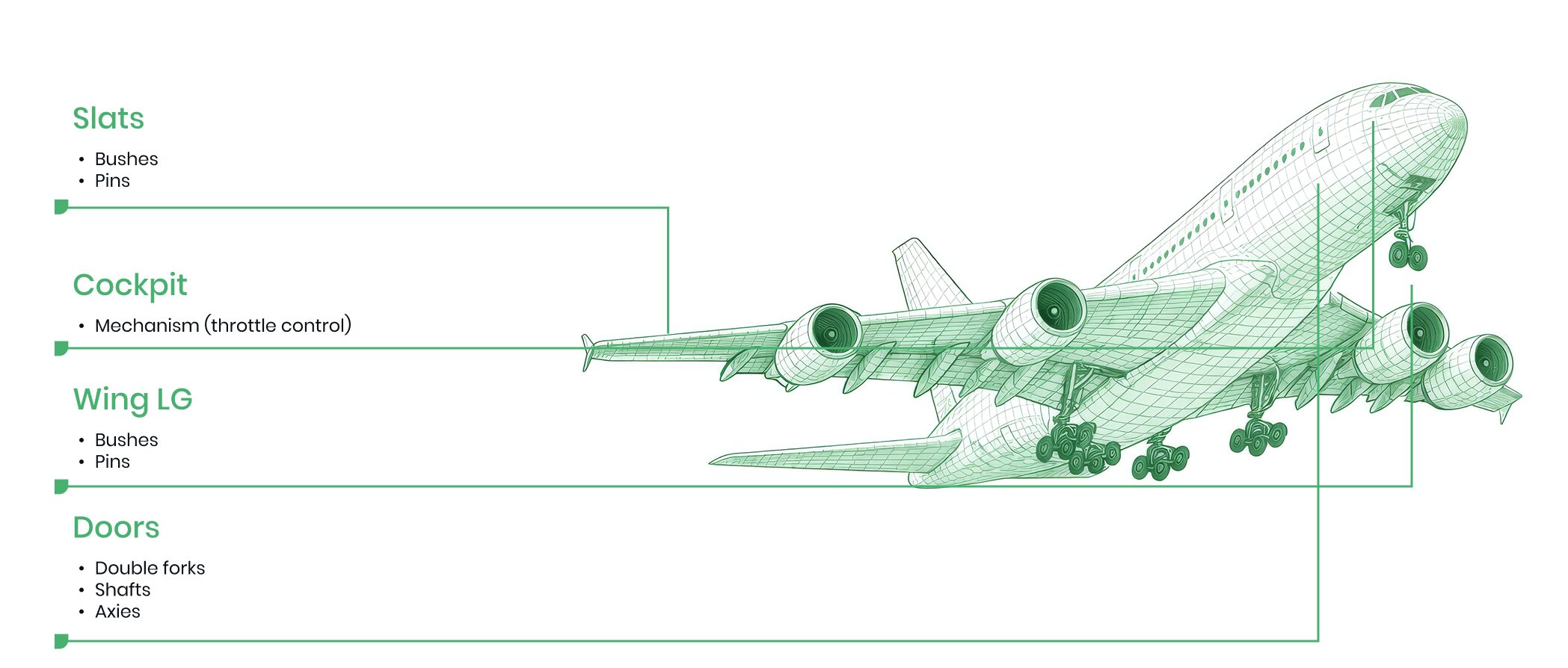

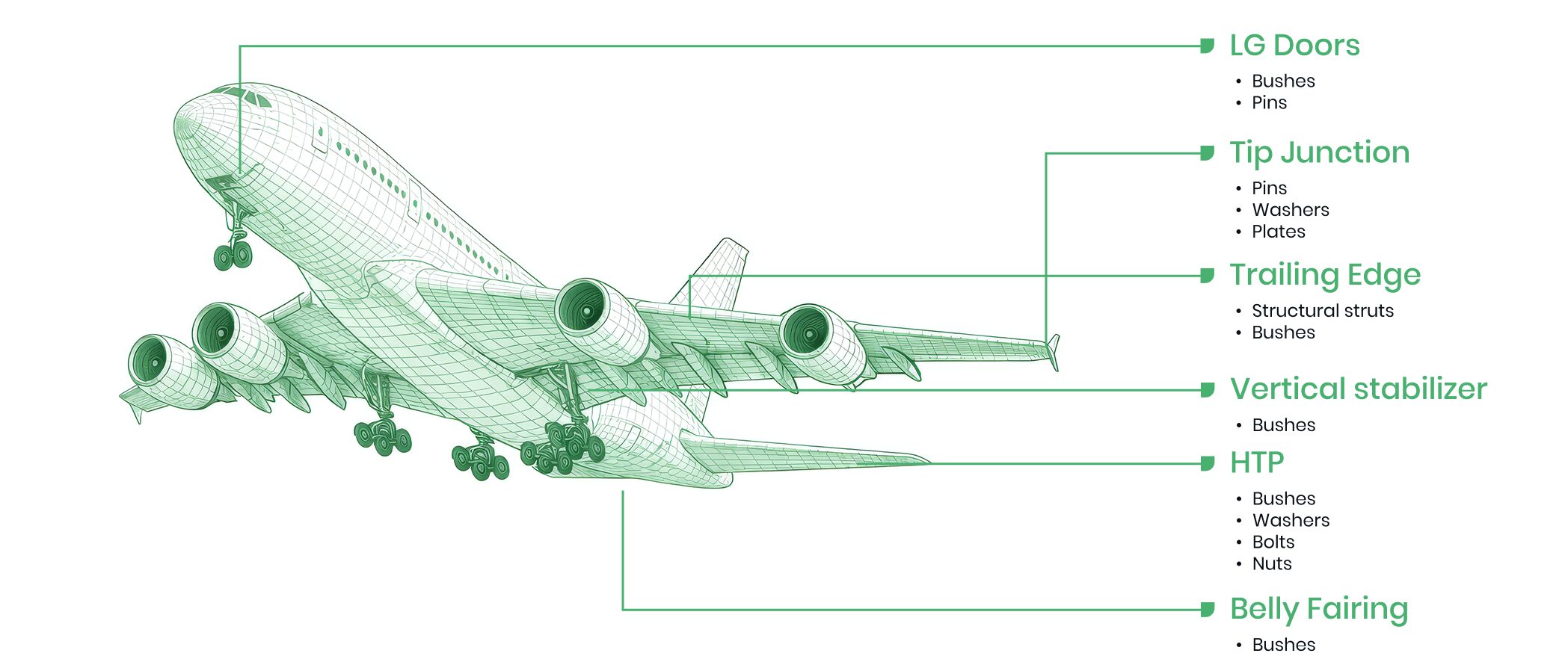

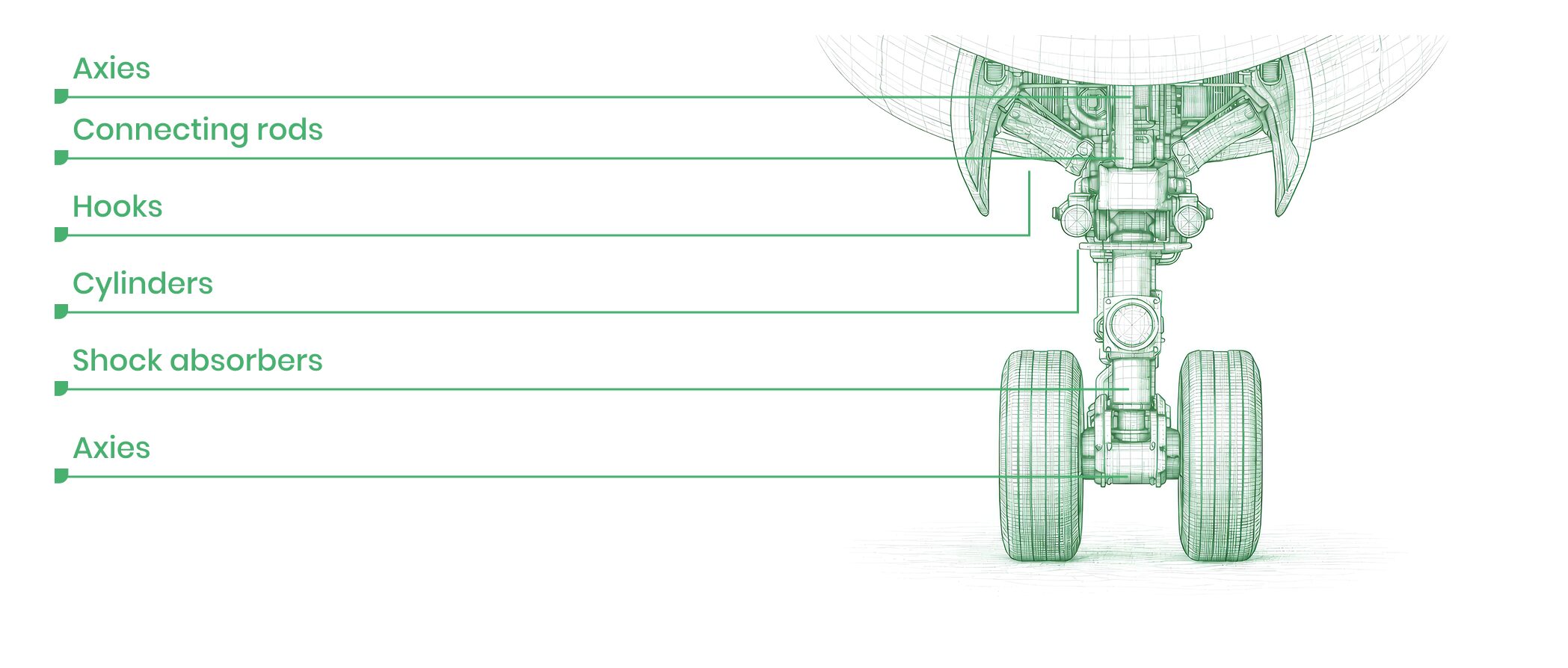

Typical aerospace applications

Landing gear sub assemblies, actuators & cylinders, brackets & fasteners, structural hardware; applicable to defense aerospace, space applications and MRO environments.

Certifications & standards

NADCAP

Global standard for aeronautics critical process accreditationSystem

Isigny-le-Buat

ISO 9001 / IATF 16949

ISO 14001

Environmental Quality Management System

Isigny-le-BuatSaumurČeský DubTřemošnice Bielsko-Biała Nowa Sól

ISO 45001

Health and Safety Management System

Český DubTřemošnice

Tisax assesment

Information security management system

Český DubTřemošnice Bielsko-Biała Nowa Sól

Need specific support

Talk to our technical teams

Are you developing a new component, have specifications to validate or are you encountering a functional or regulatory constraint?

Our technical teams are at your disposal to study your needs and build a suitable solution.

Tailor-made solutions

See how we develop customized surface treatment solutions to address unique technical challenges and specific requirements.

THEY TRUST US

We are serving more than 300

customers

solutions for

your industry

MOBILITY

AERONAUTIC

DEFENSE

GENERAL INDUSTRY

FAQ

What electroless nickel plating (ENP) specifications do you offer for wear resistance on aircraft hydraulic components?

For aircraft hydraulic components, ENP specifications are defined according to functional requirements and applicable aerospace standards.

High phosphorus electroless nickel coatings are commonly used to provide corrosion resistance, chemical stability and reliable wear performance under pressure and tight tolerances.

Final specifications are defined in accordance with customer drawings and qualification procedures.

Are your aerospace coating processes NADCAP accredited or compliant with AS9100 standards?

Our aerospace coating activities operate within an AS9100-certified quality management system.

In addition, our zinc-nickel plating process and line for aeronautics is NADCAP certified within the applicable scope. Certification and accreditation details can be confirmed depending on the coating process and application.