Defense & Military Surface Treatment Solutions

Electropoli contributes to sensitive Defense programs by treating components exposed to extreme conditions such as corrosion, abrasion, and REACH-regulated environments. Multi treatments, advanced finishes, and cadmium-free alternatives have been developed and validated under real-world constraints.

Examples of mastered processes include zincnickel (ZnNi), electroless nickel (ENP), Surtec 650 / Alodine chemical conversion, liquid painting, ecoat, phosphating….

Surface treatments for defense industry

Our defense-grade coating technologies are engineered to deliver MIL-SPEC durability and operational reliability.

Explore our advanced military surface treatments, engineered to meet defense coating standards and provide extreme corrosion, abrasion, and chemical resistance (CARC) with low-reflectivity camouflage properties for all tactical and electronic systems.

Typical Defense applications

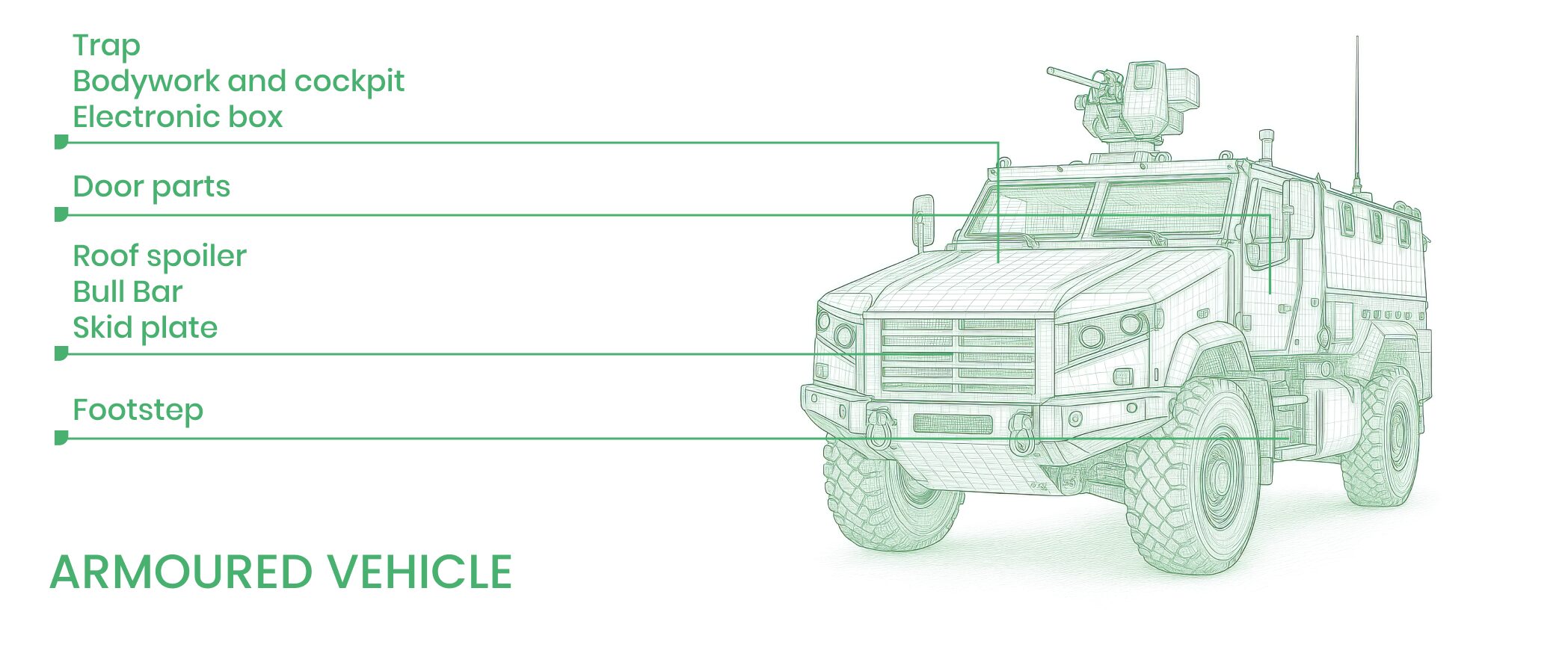

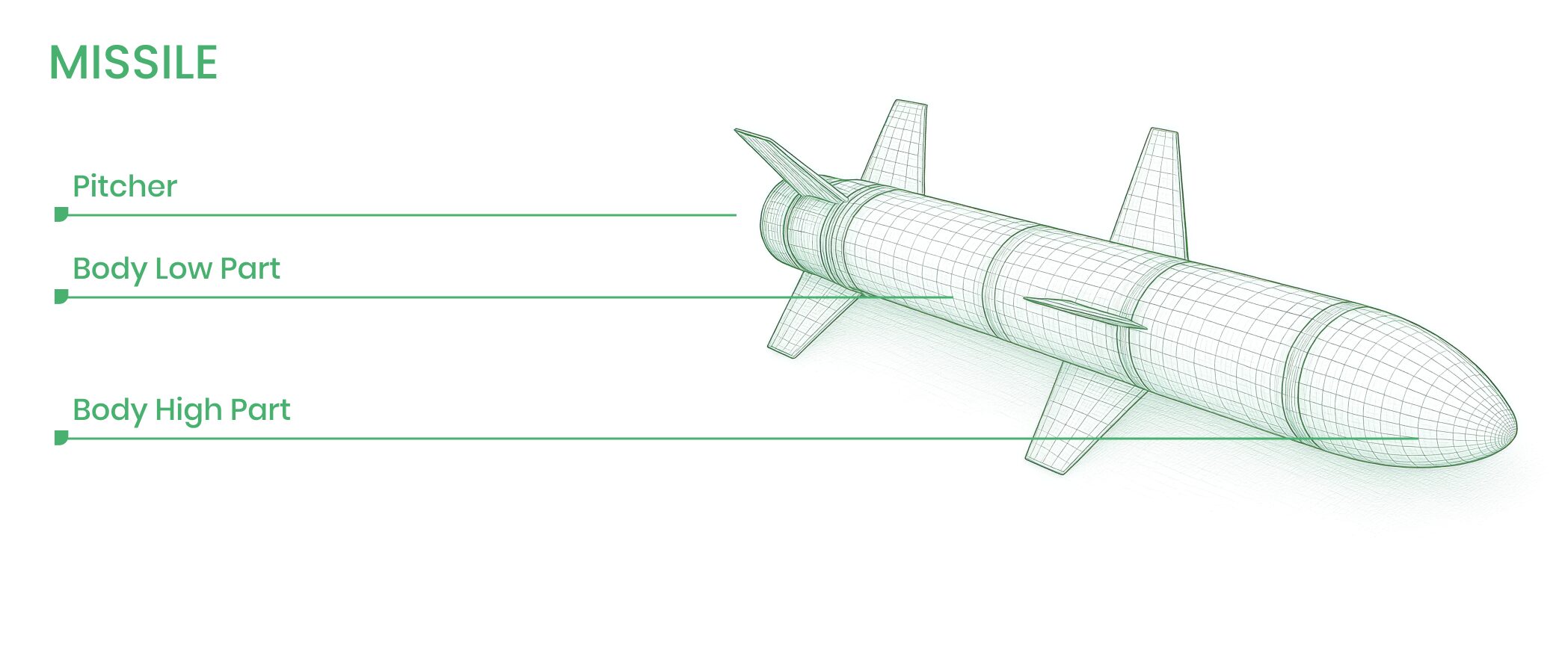

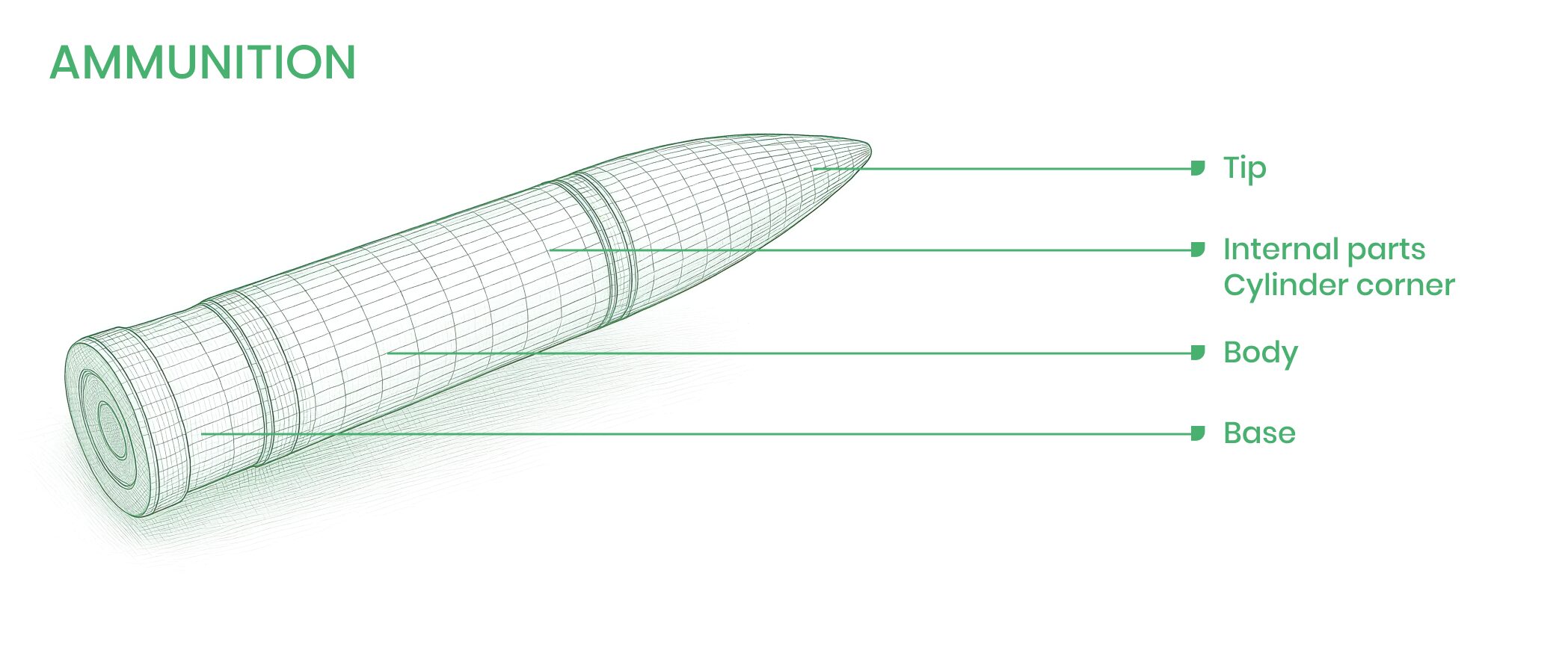

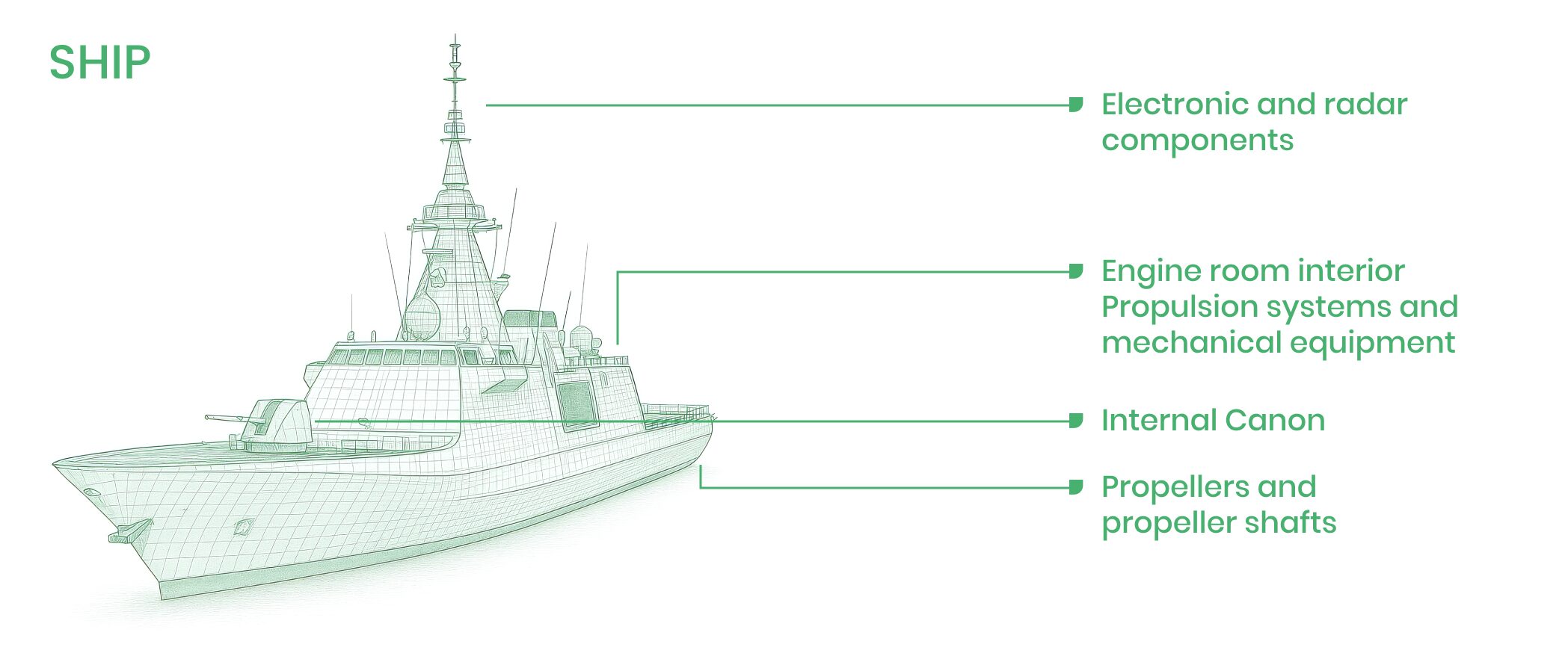

Typical Defense applications include armored and tactical vehicles components, land/air/naval subassemblies, mounts and fasteners, electronic enclosures, hydraulic parts, landinggear elements, and communication systems hardware treated to customer specifications.

Certifications & standards

ISO 9001 / IATF 16949

ISO 14001

Environmental Quality Management System

Isigny-le-BuatSaumur Český DubTřemošnice Bielsko-Biała Nowa Sól

ISO 45001

Health and Safety Management System

Český DubTřemošnice

Tisax assesment

Information security management system

Český DubTřemošnice Bielsko-Biała Nowa Sól

NADCAP

Global standard for aeronautics critical process accreditationSystem

Isigny-le-Buat

Need specific support

Talk to our technical teams

Are you developing a new component, have specifications to validate or are you encountering a functional or regulatory constraint?

Our technical teams are at your disposal to study your needs and build a suitable solution.

Tailor-made solutions

See how we develop customized surface treatment solutions to address unique technical challenges and specific requirements.

THEY TRUST US

We are serving more than 300

customers

solutions for

your industry

MOBILITY

AERONAUTIC

DEFENSE

GENERAL INDUSTRY

FAQ

What corrosion protection solutions do you offer for naval defense equipment exposed to saltwater environments?

Naval defense equipment exposed to saltwater requires high-performance corrosion protection adapted to material, environment and operational constraints.

We offer single-layer and multi-layer systems, including duplex or triplex solutions combining metallic coatings and high-performance paints to address both barrier and sacrificial protection needs. Each solution is defined in line with customer specifications and qualification requirements.

Are your electroless nickel plating processes suitable for weapon components requiring high wear resistance and tight tolerances?

Yes. Electroless nickel plating is well suited for weapon components requiring high wear resistance and tight tolerances.

The process ensures uniform deposition and precise thickness control, even on complex geometries. Duplex ENP systems and selective masking can be applied when required to meet functional and qualification requirements, in line with applicable defense standards.