Surface treatments for Mobility industry

Electropoli provides high-performance coatings and metal finishing solutions for the Mobility industry, including automotives, heavy vehicles and motorbikes.

Our corrosion protection meets the OEM specifications and quality standards, ensuring durability, efficiency, and compliance across all components — from chassis and powertrain parts to fasteners and body systems.

Surface treatments for Mobility industry

Our expertise in mobility surface treatment covers every step of component protection — from corrosion prevention to paint preparation and decorative finishing.

Explore our recommended processes designed to meet OEM requirements and ensure durability across all vehicle types.

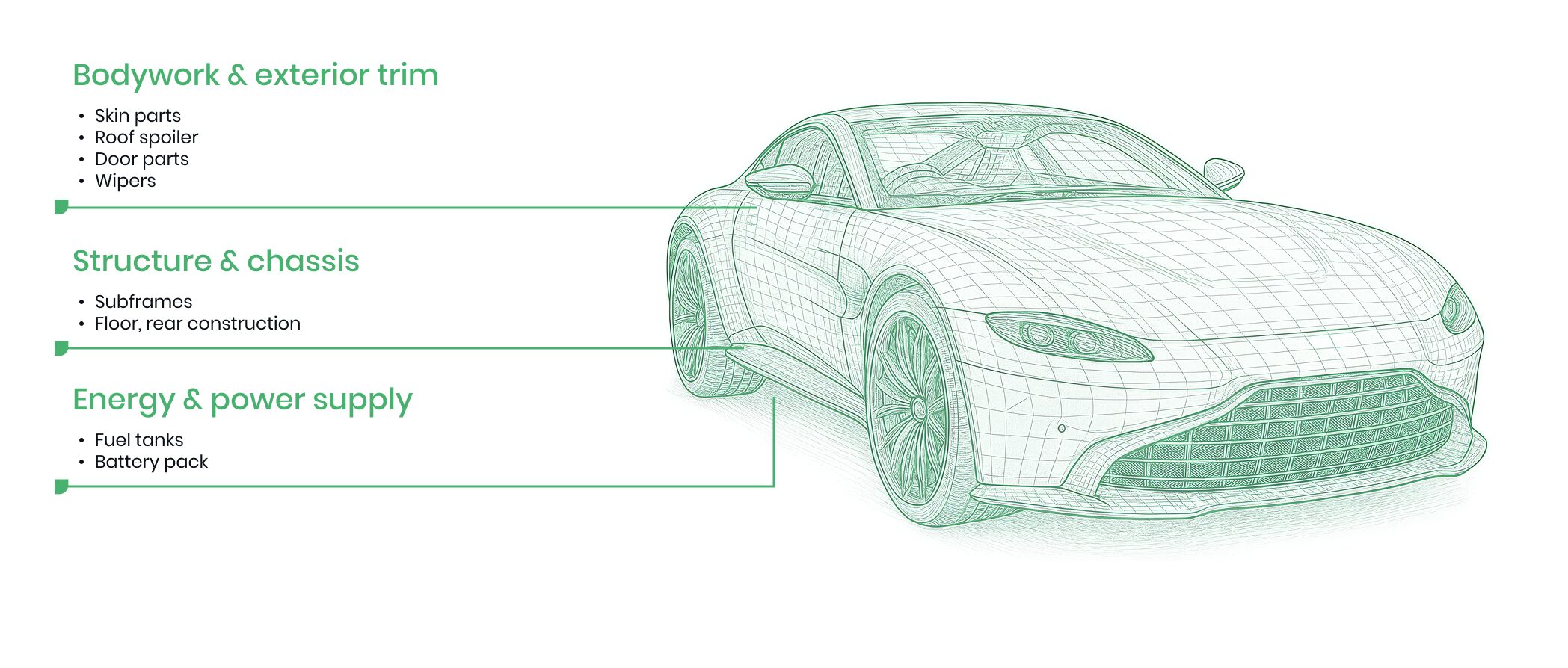

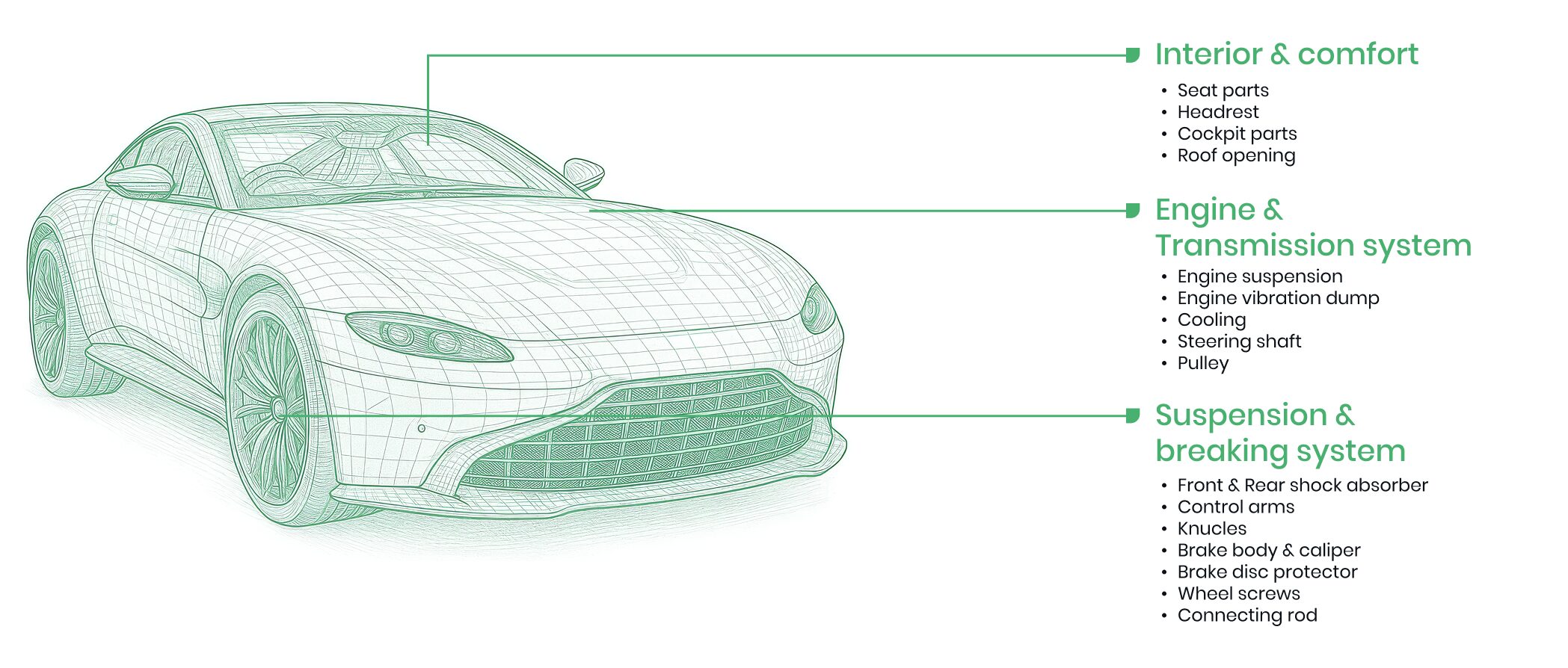

Typical Mobility applications

Certifications & standards

ISO 9001 / IATF 16949

ISO 14001

Environmental Quality Management System

Isigny-le-BuatSaumurČeský DubTřemošnice Bielsko-BiałaNowa Sól

ISO 45001

Health and Safety Management System

Český Dub Třemošnice

ISO 50001

Energy Management System

Český Dub Třemošnice

Tisax assesment

Information security management system

Český Dub Třemošnice Bielsko-Biała Nowa Sól

Need specific support

Talk to our technical teams

Are you developing a new component, have specifications to validate or are you encountering a functional or regulatory constraint?

Our technical teams are at your disposal to study your needs and build a suitable solution.

Tailor-made solutions

See how we develop customized surface treatment solutions to address unique technical challenges and specific requirements.

THEY TRUST US

We are serving more than 300

customers

solutions for

your industry

MOBILITY

AERONAUTIC

DEFENSE

GENERAL INDUSTRY

FAQ

What are the best corrosion protection coatings for automotive underbody components exposed to road salt?

Automotive underbody components are exposed to highly aggressive conditions such as road salt, moisture and stone chipping. To ensure long-term corrosion protection, several coating solutions are commonly used, often in combination.

Zinc-based coatings, such as zinc-nickel plating, provide sacrificial corrosion protection, while cataphoretic painting (KTL) and powder coating act as durable barrier layers. KTL is particularly effective for complex geometries.

For the most demanding applications, duplex systems combining zinc-based coatings with KTL or powder paint offer enhanced durability and extended service life. The final solution is defined according to component design, exposure level and OEM specifications.

Do your E-coat (KTL) services meet automotive OEM specifications for salt spray resistance and adhesion?

Yes. Our E-coat (KTL) processes are qualified to meet major automotive OEM specifications for salt spray resistance and coating adhesion.

Performance is validated through standardized and OEM-specific tests, supported by controlled pretreatment, stable process parameters and adapted coating thickness. All treatments are regularly tested and fully traceable, in line with automotive quality requirements.

Can you provide Zinc-Nickel plating as a cadmium replacement for brake system parts in trucks?

Yes. Zinc-Nickel electroplating is a proven cadmium replacement for brake system components in trucks and commercial vehicles.

It offers high corrosion resistance and stable performance in severe environments while meeting regulatory requirements such as REACH. The coating system is defined according to component design and applicable specifications.

What surface preparation and pretreatment do you recommend before powder coating aluminum motorbike frames for optimal durability?

For aluminum motorbike frames, proper surface preparation is essential to ensure corrosion resistance and durable powder coating adhesion.

Pretreatment typically includes cleaning and surface activation, followed by a conversion treatment based on chromium-free or trivalent chromium (Cr³⁺) passivation. The final pretreatment sequence is defined according to the aluminum alloy, exposure conditions and durability requirements.

How do your duplex coating systems (e.g., plating + E-coat) improve the lifespan of heavy vehicle chassis in harsh environments?

Duplex coating systems combine a metallic coating (such as zinc or zinc-nickel) with an organic topcoat like E-coat (KTL) to improve corrosion protection in harsh environments.

The metallic layer provides sacrificial protection, while the E-coat acts as a durable barrier against moisture and road salt, even on complex geometries. This synergy significantly extends the service life of heavy vehicle chassis. The final system is defined according to design and performance requirements.