Versatile surface treatments for diverse general industry applications

Electropoli delivers versatile industrial coating solutions for the general manufacturing sector, ensuring durability, corrosion protection, and performance optimization.

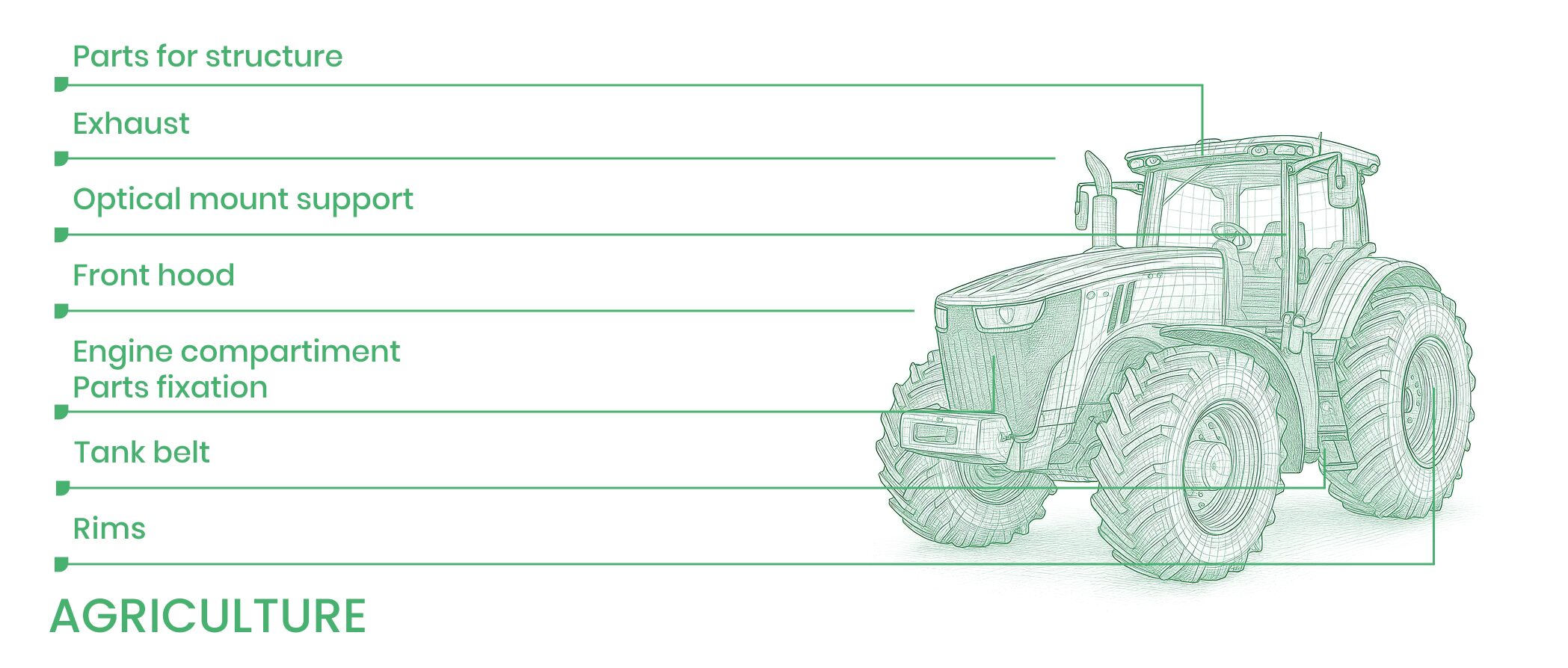

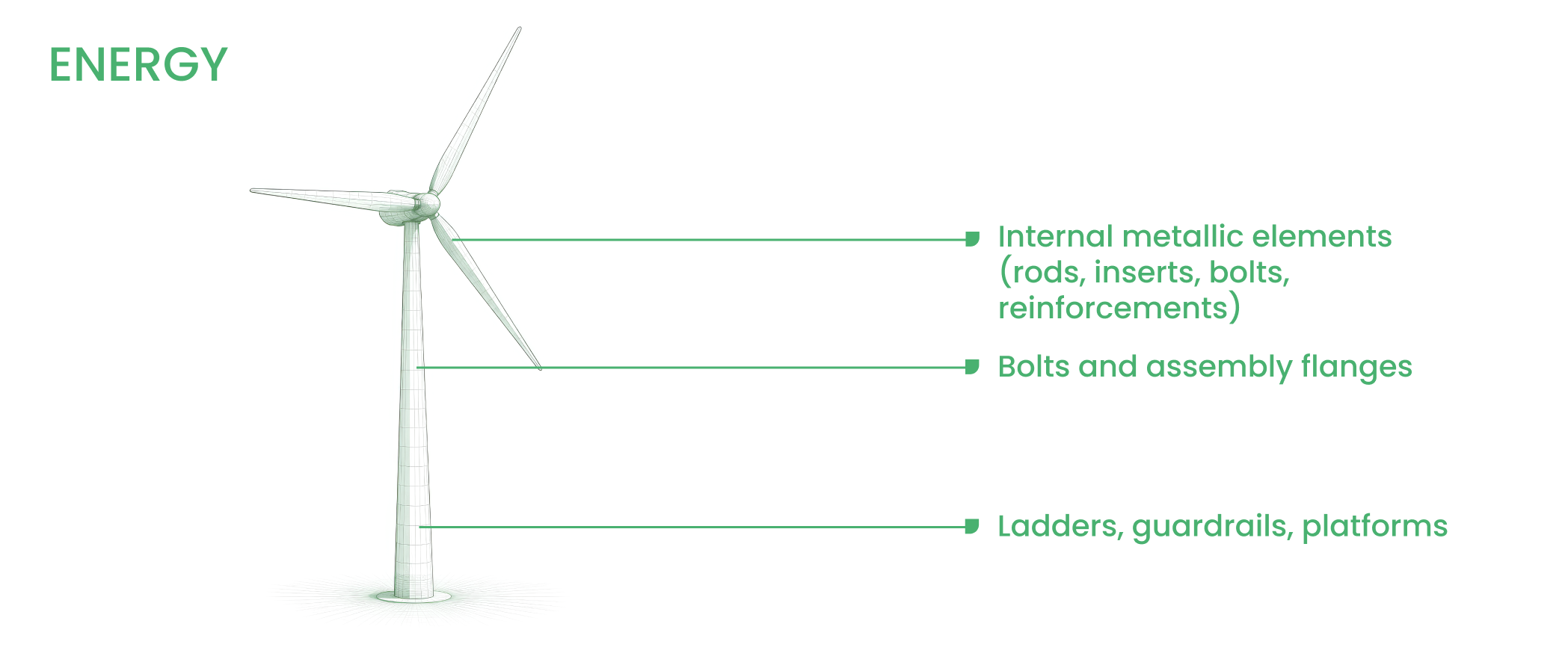

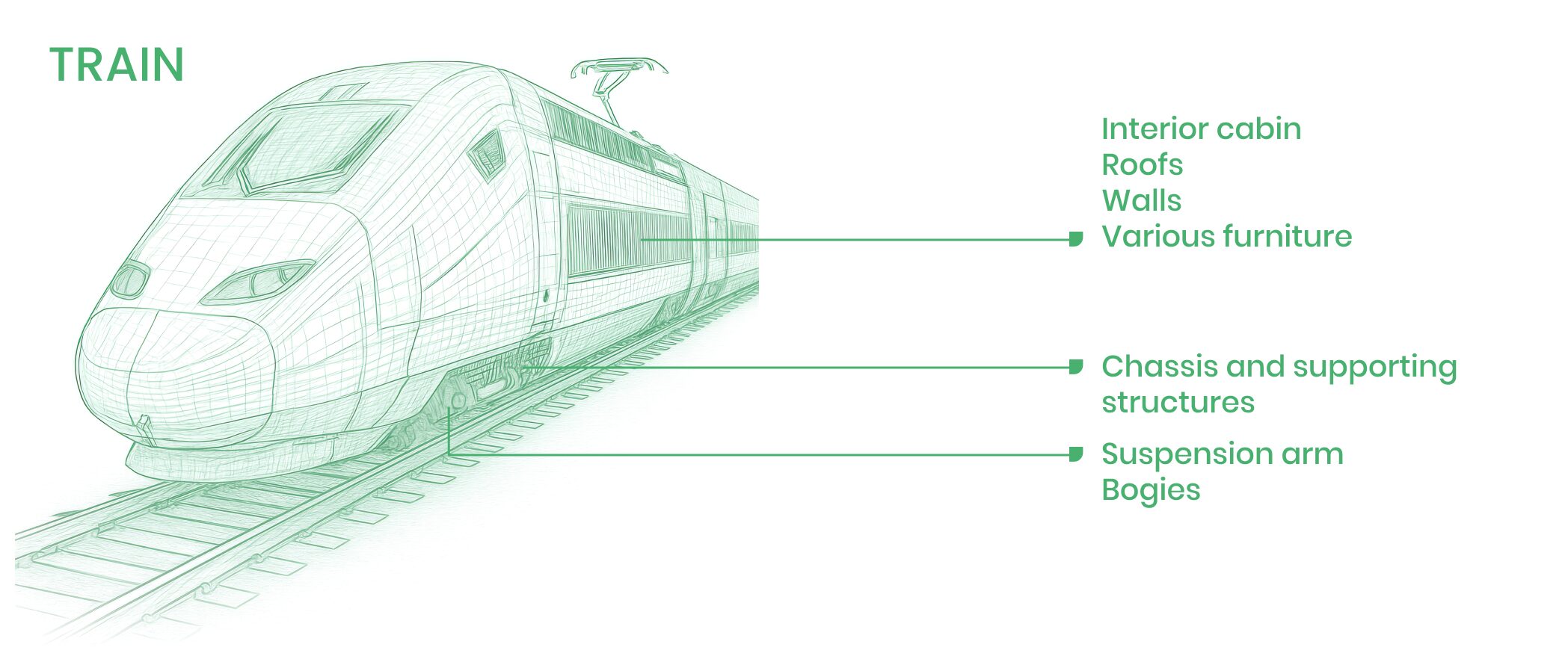

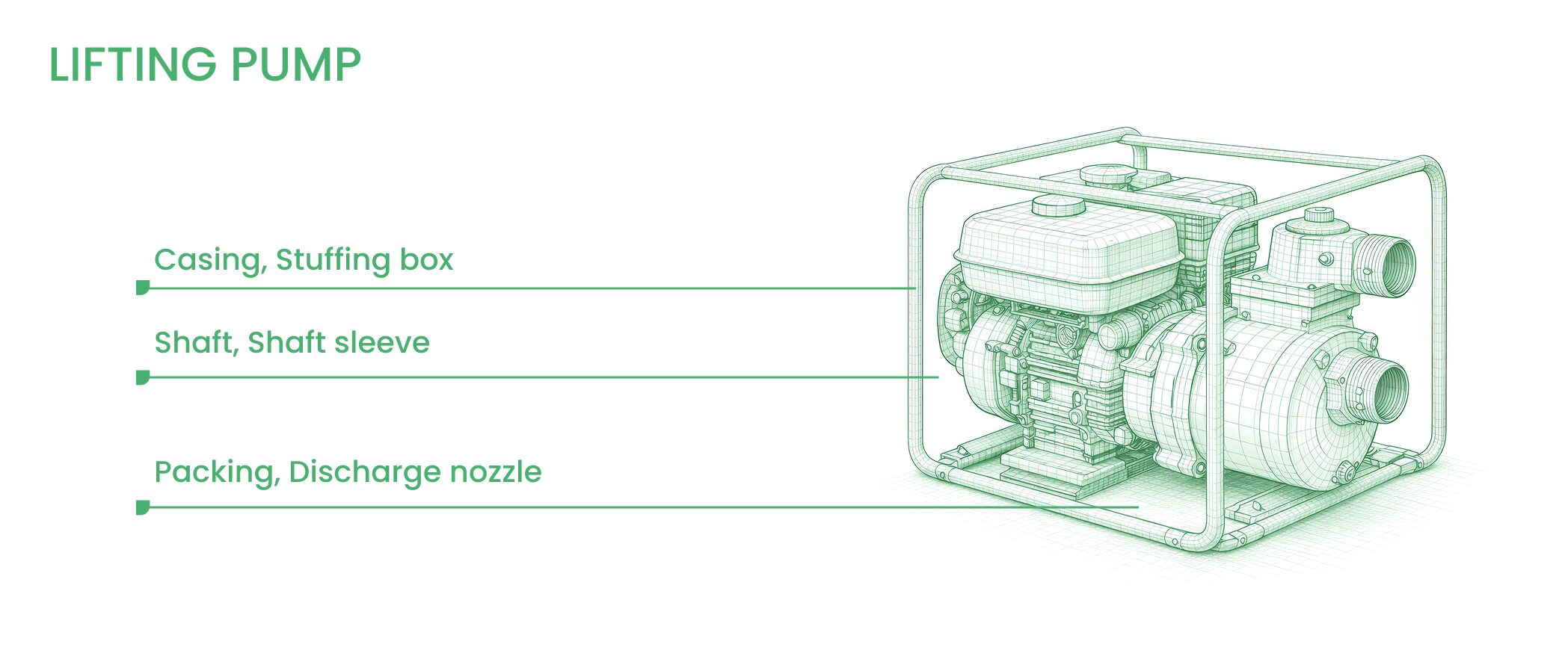

Our expertise in surface treatment caters to a wide variety of industrial components and production requirements, whether in agriculture, energy, oil and gas, railways, industrial applications, leisure, etc.

Surface treatments for general industry

Explore our advanced coating and finishing solutions designed to protect, enhance, and extend the life of industrial components. From robust zinc plating and electroless nickel for precision parts to advanced e coat primers, powder and liquid paints, our portfolio meets the most demanding general industry needs. We also provide phosphating for superior paint adhesion, aluminum passivation for lightweight assemblies, and duplex systems, multilayer coating systems for maximum durability.

Typical applications for general industry

Explore a selection of parts typically protected by our processes:

RAILWAY | ENERGY | AGRICULTURE | OIL GAZ | LEISURE

Certifications & standards

ISO 14001

Environmental Quality Management System

Isigny-le-BuatSaumurČeský DubTřemošnice Bielsko-Biała Nowa Sól

ISO 45001

Health and Safety Management System

Český DubTřemošnice

Tisax assesment

Information security management system

Český DubTřemošnice Bielsko-Biała Nowa Sól

Need specific support

Talk to our technical teams

Are you developing a new component, have specifications to validate or are you encountering a functional or regulatory constraint?

Our technical teams are at your disposal to study your needs and build a suitable solution.

Tailor-made solutions

See how we develop customized surface treatment solutions to address unique technical challenges and specific requirements.

THEY TRUST US

We are serving more than 300

customers

solutions for

your industry

MOBILITY

AERONAUTIC

DEFENSE

GENERAL INDUSTRY

FAQ

What is the most cost-effective corrosion protection solution for steel components used in general manufacturing?

There is no single cost-effective solution in all cases. The optimal corrosion protection depends on component requirements, production volumes, exposure conditions and expected service life.

For many steel parts in general manufacturing, cataphoretic coating (E-coat / KTL) offers a good balance between cost, coverage and durability. In less aggressive environments, simpler solutions such as zinc plating or basic painting systems may be sufficient. Cost-effectiveness is ultimately evaluated based on total cost of ownership.

What pretreatment do you recommend before painting agricultural machinery parts to ensure long-term durability in outdoor conditions?

For agricultural machinery parts exposed to outdoor conditions, pretreatment is essential to ensure corrosion resistance and paint adhesion.

Pretreatment is defined according to the base material and service conditions and typically includes cleaning, surface activation and a conversion treatment such as phosphating or passivation. For steel parts requiring higher durability, this can be combined with E-coat or zinc-based plating before liquid painting. The final solution is selected according to durability requirements and customer specifications.

Do you offer E-coat (KTL) as a primer for complex shaped industrial components to achieve uniform coverage before top coating?

Yes. E-coat (KTL) is well suited as a primer for complex shaped industrial components where uniform coverage is required.

Its electrochemical deposition process ensures consistent thickness on edges, cavities and recessed areas, making it an effective base layer before liquid or powder topcoats. The final coating system is defined according to component geometry and performance requirements.

What are the typical turnaround times for batch zinc plating of standard industrial hardware?

Turnaround times depend on batch size and production planning. For standard industrial hardware, lead times are typically a few working days from receipt to delivery. Depending on capacity and priority, processing can start within around 72 hours.