R & D

A R&D center at the service of industrial performance, technologic innovation and sustainable responsibility with 31 patents/trademarks filed since 1992.

« Useful innovation, sustainable industrialization.

Our ambition is to combine industrial performance, technological innovation, and environmental responsibility. We transform your needs into robust, scientifically validated solutions, which are then transferred into production at our European sites.

Our priorities: high performance, energy efficiency, replacement of CMR substances, and REACH anticipation.

Together with our customers and partners, we are designing today the surface treatments of tomorrow. »

Denis MORICE

Group R&D Director

A structured method, from the laboratory to industrial transfer

Our approach covers initial scoping, laboratory testing, formulation, corrosion testing, feasibility validation, pilot lines, and finally, on-site transfer.

This approach guarantees reproducibility, risk control, and reliable deployment across multiple plants when necessary.

An integrated R&D center dedicated to industrial performance

Based in France and accredited by the Research Tax Credit (CIR), our Electro-Research center brings together engineers, doctors of chemistry, technicians, and specialized students.

With the support of our factories, they develop new baths, optimize existing processes, and support large-scale industrialization.

Our analytical resources guarantee the quality and reliability of results:

Advanced analyses: ICP, chromatography, X-ray fluorescence, scanning electron microscopy.

Multiple cyclic corrosion tests: salt spray (SS), CASS, ECC1.

Physical measurements: thickness, adhesion, internal stresses…

Pilot lines for technical validation prior to industrial deployment.

Our key areas of expertise

We focus our efforts on the major challenges facing the industry:

· Developing solutions that comply with new regulations (REACH, PFAS, RoHS).

· Design of low-emission processes optimized for energy and water consumption.

· Substitution of hexavalent chromium and CMR substances.

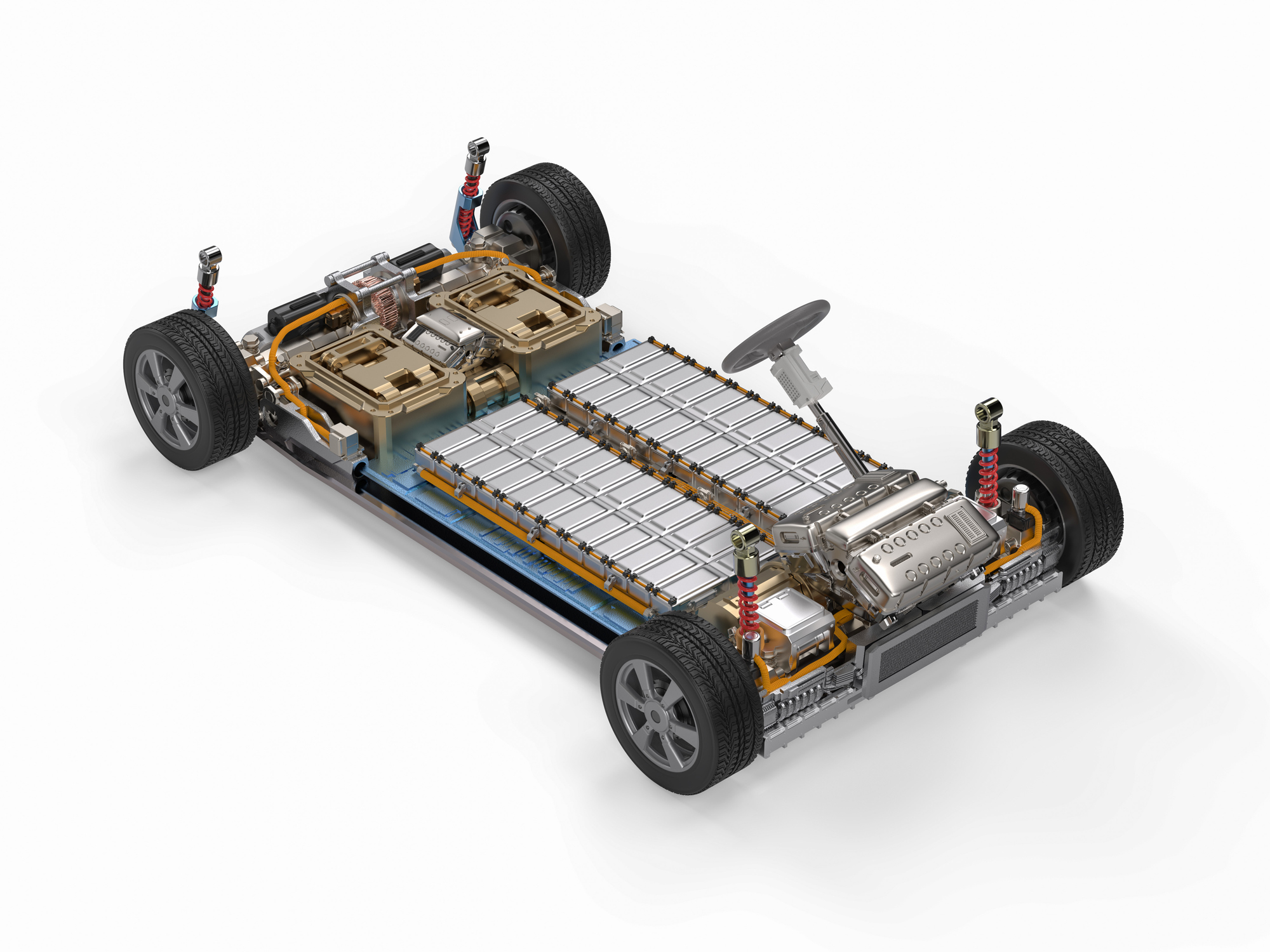

· Treatments adapted to materials of the future: light alloys, batteries, magnets, electric mobility devices.

We create now the future of surface treatments

Our project portfolio covers industrial and academic partnerships, with 31 patents already filed since 1992.

Tailor made services

Collaborative developement

At Electropoli, we design tailor-made surface treatment solutions in close collaborations with our customers.

Our ambition is to create sustainable, innovative processes that meet the technical and envrionmental requirements of each application – automotive, aeronautics, defense, and beyond.

From idea to industrialization

From analysis of specific needs to industrial validation, Electropoli adapts products and processes – preparation, treatments, finishing – to your parts from the design phase.

Prototyping, pre-series testing, co-engineering, and dedicated tooling ensure a complete, reliable industrialization process.

concrete examples of

developments

Electropoli industrializes a customized surface treatment solution for large electric battery components

Electropoli industrialises a customised surface treatment solution for coupling drill pipe sleeves

Do you have a project?

An idea to develop?

A specific need to be validated?

LET’S TALK TOGETHER.

+33 (0)6 87 80 43 26

By collaborating with Electropoli, which is CIR approved, your R&D projects can benefit from a 30% tax credit.